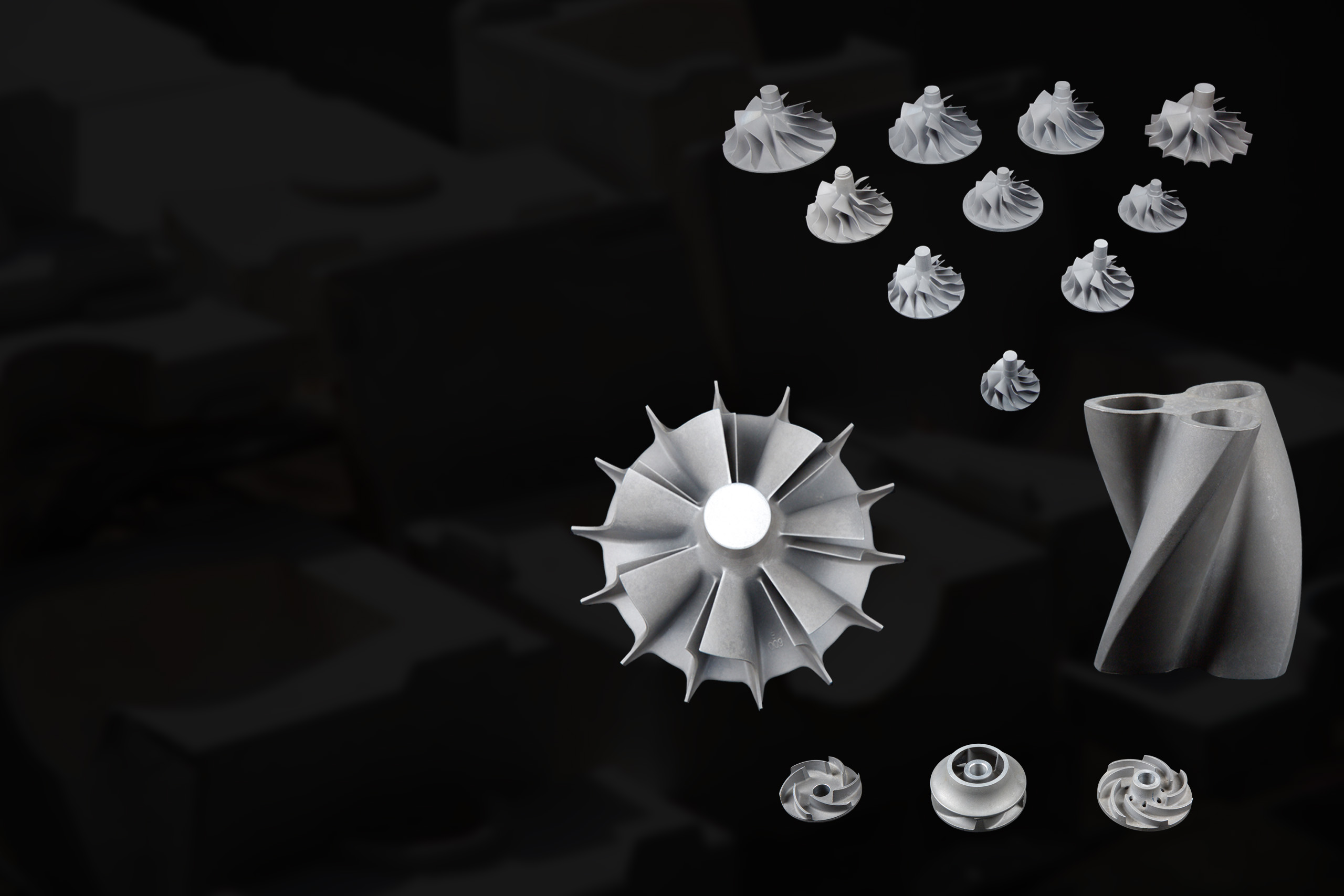

Casting

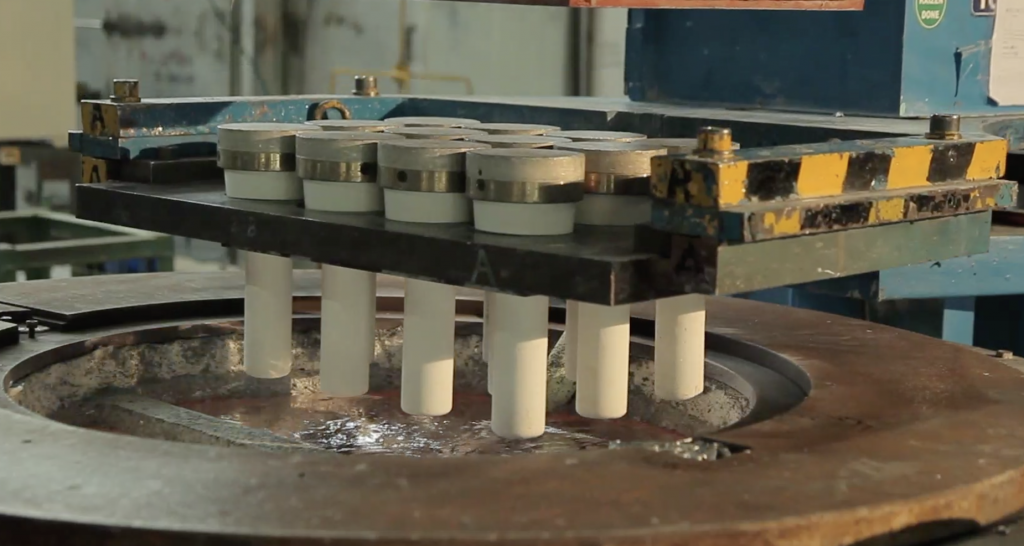

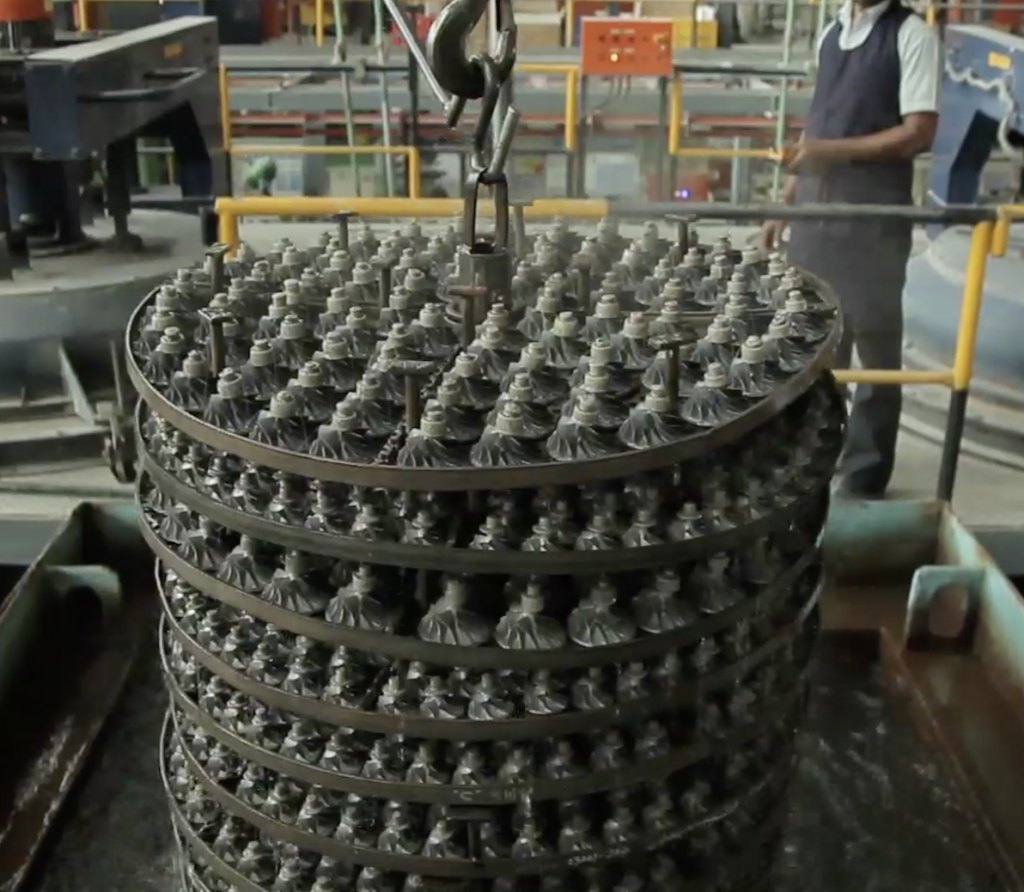

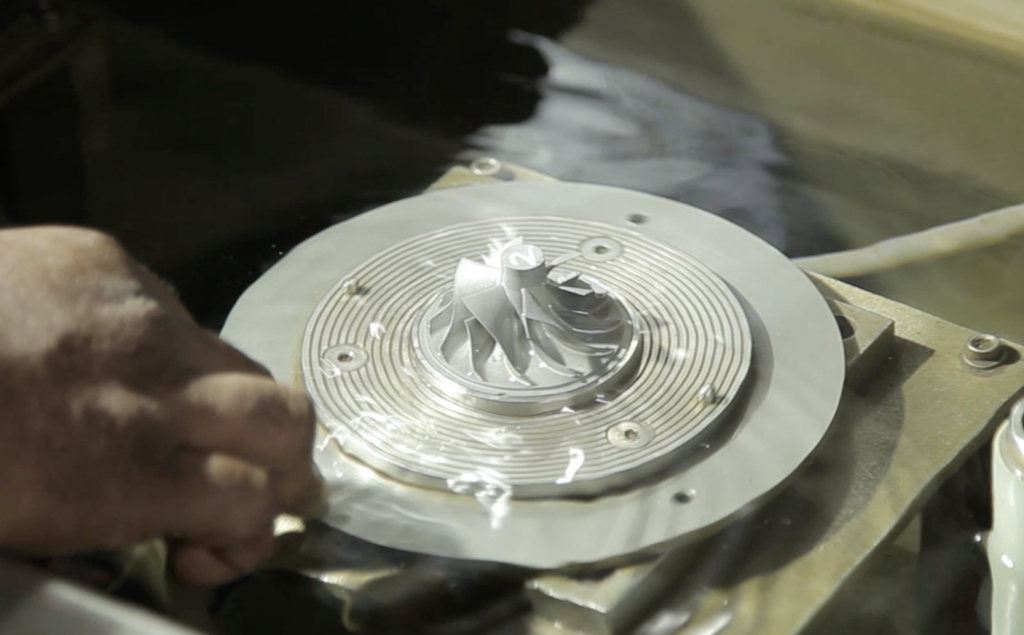

The casting machines use a vacuum-assisted counter gravity process for casting. ABI has in-house Hot Isostatic Pressing and heat treatment facilities. ABI currently supplies a range of wheels, from a minimum size of 30mm to a maximum size of 200mm in diameter. The process is capable of manufacturing wheels with blade thickness of as low as 0.3mm.