Melting Facility

ABI is equipped with two melting furnaces.

- 1.5 Tonnes/Hr furnace

- 1 Tonne/Hr furnace

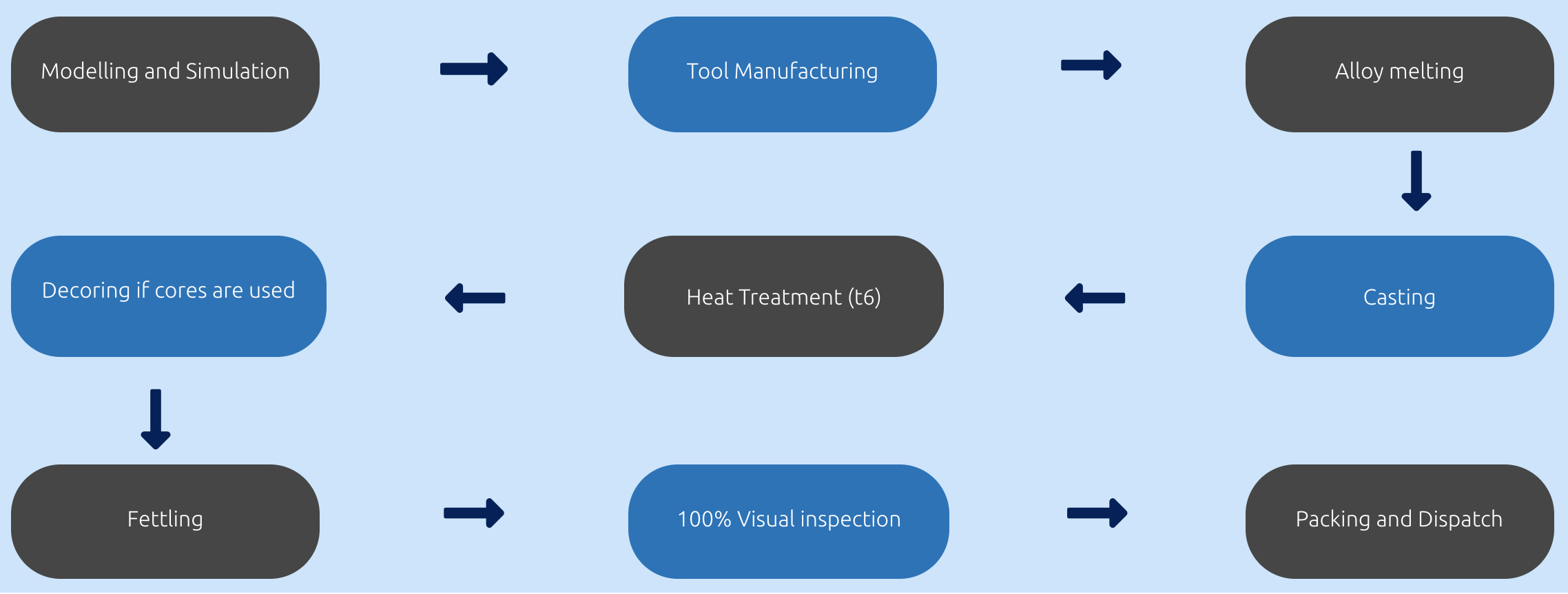

Casting

ABI’s facility is equipped with seven, eight station carousels with ability to load single or multi-cavity dies. Metallic inserts and sand cores are used to create the hollow portion in the parts. The shell cores from the core drying ovens are directly transferred to the casting machines through a conveying system.