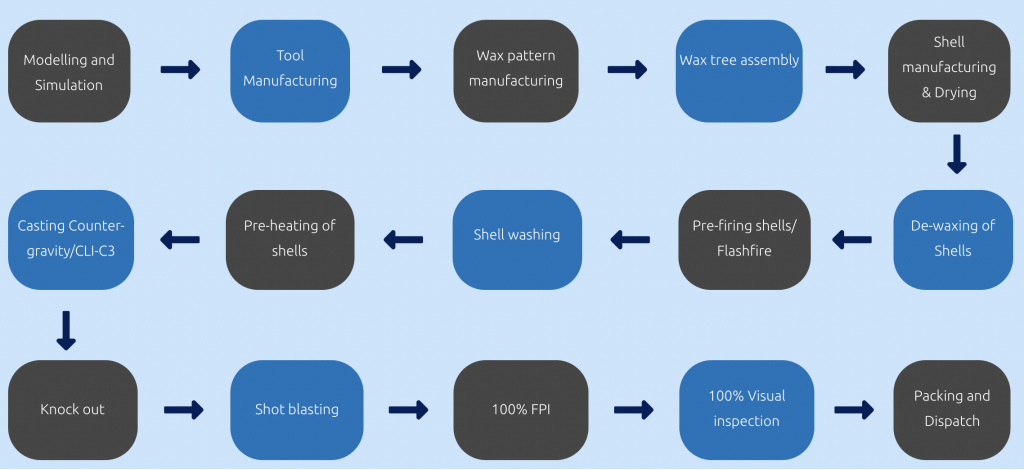

Countergravity / CLI-C3 Process

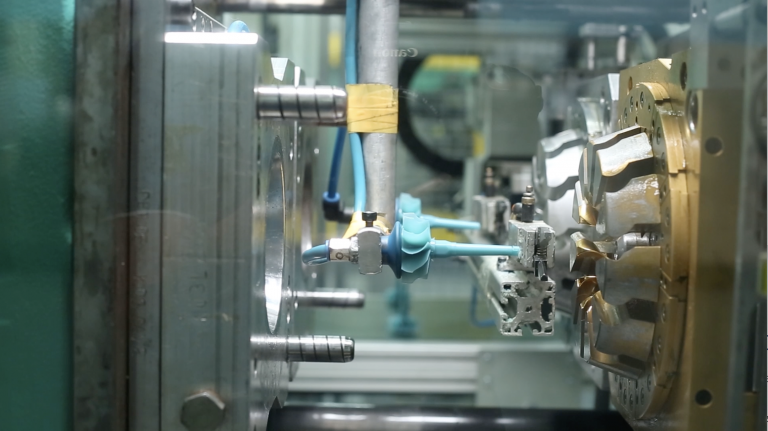

The casting process used is a proprietary process called CLI-C3. The process combines counter gravity, low pressure and centrifugal force to enable quick and efficient casting

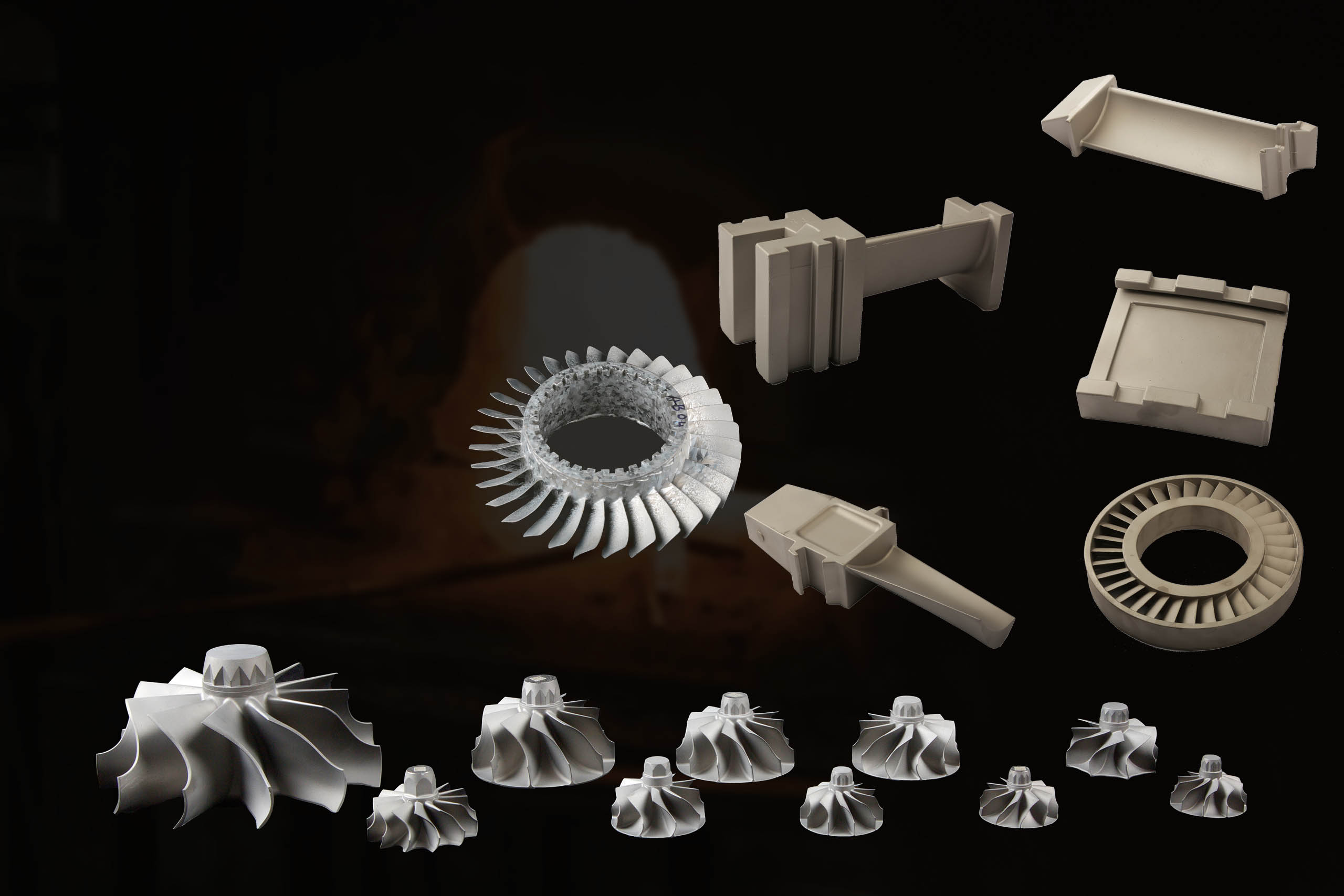

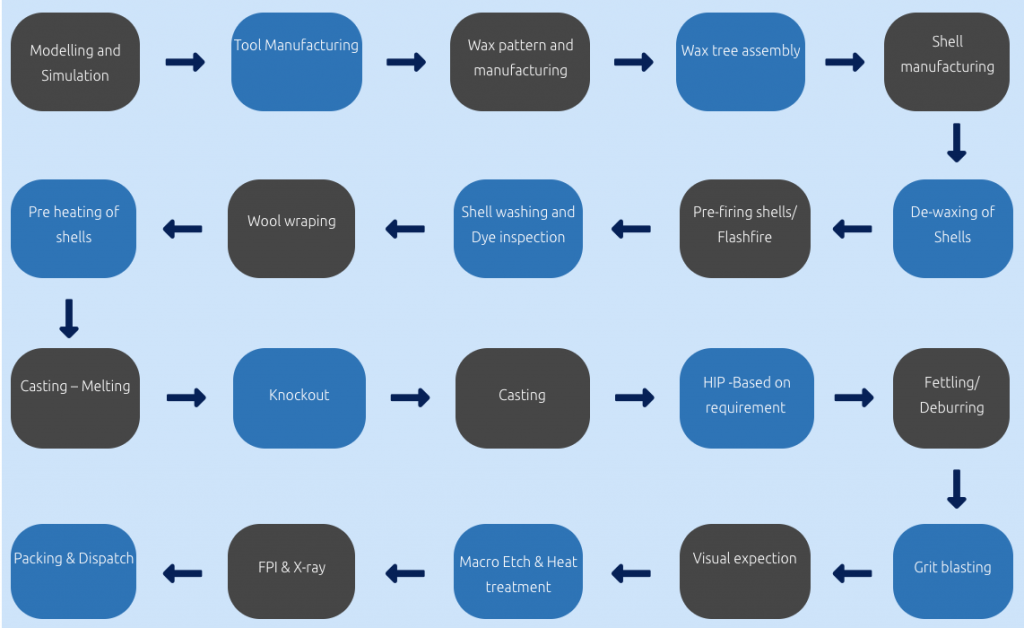

ABI’s Investment casting process is extremely versatile and is excellent for complex components where customers require thin parts with high dimensional accuracy.

Currently ABI supplies a range of Turbine wheels, with the minimum size of 30mm to a maximum size of 90mm in diameter. The process is capable of manufacturing wheels with a blade thickness as low as 0.35 mm.

In the Investment casting foundry, ABI can produce turbine wheels, waste gate parts and many other precision engineering components.